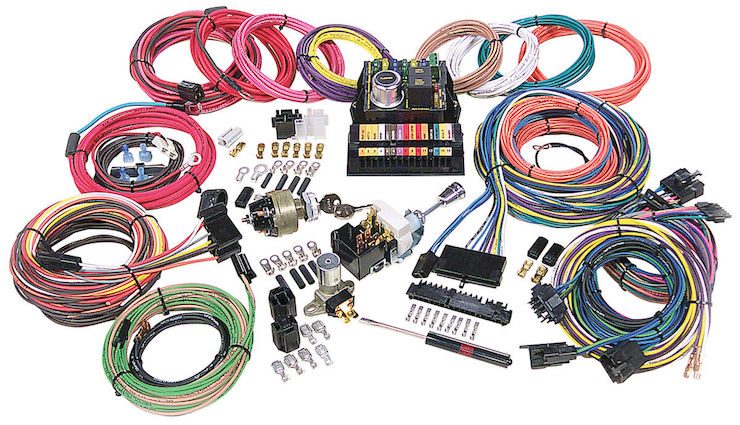

An In-Depth Look at Wiring Harnesses

The wiring harness in your car is an essential component. If it functions correctly, you'll never give it a second thought. If it functions poorly, it will be the source of a myriad problems, big and small.

Therefore, it's never a good idea to cut corners when purchasing a wiring harness. You want to invest in a carefully designed harness with high quality materials, and we're going to explain why. We're also going to explain what some of the basic components are in each harness, so that you can make sure to get a harness that meets your needs.

Standard Wiring Harness Components

There are a variety of parts and components in automotive wiring harnesses, each of which has a specific purpose.

A relay is used in automotive wiring for high-load circuits where a simple switch would be burned out (at least over time). Think of a relay as an electrically actuated switch, designed specifically for high current circuits. Instead of using an ignition switch to actuate a vehicle's starter, for example, an ignition switch is designed to actuate a relay, which then sends current to the starter.

Basically, relays use a low current signal (usually from a switch) to actuate a much more powerful current. If the relay burns out, it's easy and cheap to replace.

A fuse is a 'sacrificial' circuit that is designed to melt/burn out at a certain current level. For example, a 5 amp (5A) fuse is designed to burn out if it carries more than 5 amps of current. Fuses protect various electrical accessories from damage, which is most often caused by a short circuit somewhere in the harness. It's essential to have a fuse on every circuit in your harness, as that protects you and your vehicle from damage (short circuits can cause fires).

Most modern automotive electrical systems use 'blade' type fuses, as they're reliable, easy to read (they're color-coded, with the fuse color indicating the amperage), and they're very affordable. Older automotive electrical systems (pre-1980s) often use a glass tube type fuse rather than a blade fuse. Generally speaking, newer blade type fuses are the best choice for a wiring harness. They're less susceptible to damage from vibration and easy to read.

A fuse block is a central point where all fuses can be kept. This way, if/when there's an electrical accessory that's non-functional, the fuse can be found quickly and easily.

A connector is the piece of metal that's used to connect a length of wire to a fuse block, switch, accessory, or another length of wire. Connectors can be simple (like a spade or ring terminal) or complex (like Weather-Pack connectors, which are designed to be rugged and waterproof). The type of connector varies by application, but the best connectors are typically made from copper or brass. These metals are superior because of their high conductivity, and because they're more resistant to oxidation than aluminum.

Aluminum, while conductive, oxidizes almost immediately and this layer of oxide has very low conductivity. However, since aluminum is very inexpensive, most automotive wiring harness manufacturers use this material for their connectors. Copper and brass work much better, but they're considerably more expensive, so they're not used as frequently.

Connectors connect wires to the fuse block in one of two ways: crimping or crimping and soldering. Crimping is used by nearly all wiring harness manufacturers, and when it is done correctly, it's a decent connection method. The 'trick' is to make sure all the strands of each individual wire are included in the crimped connection. If a strand of wire isn't included in the crimp, the connection causes wiring harness voltage to drop.

Additionally, some wiring harness manufacturers (like American Autowire) will crimp AND solder their connectors, providing an additional level of conductivity and durability.

Finally, the wire itself is another vital component for a high quality harness. Many harnesses use a copper blend wire, as it reduces the cost of the wiring. High quality harnesses - as well as modern OEM harnesses - utilize pure copper wiring due to it's better conductivity. Blended wiring acts as a resistor, dropping voltage over longer lengths.

Standard Automotive Wiring Harness Circuits

The most basic automotive wiring harness will typically contain 12 "circuits", or lengths of wire for a specific purpose, with a designated fuse holder in the fuse block for each circuit:

- Radio

- Wipers

- Turn Signals

- Gauges

- Stop Lights

- Horn

- Hazard Flasher

- Taillights

- Parking Lights

- Dash Lights

- Distributor

- Heat & A/C

Each of the circuits listed serves a vital or extremely common electrical accessory, which is why most wiring harnesses come with at least 12 circuits. However, many vehicles have additional electrical accessories beyond those listed. An 18 circuit harness may add six circuits for power accessories, such as:

- Power Windows

- Power Locks

- Electric Fan

- Electric Fuel Pump

- High Level Stop Light

- Radio B+ Memory

And a 24 circuit harness will add wiring to support additional accessories:

- Under Hood Light

- Clock

- Lighter

- Dome Light

- Trunk Light

- Glove Box Light

As you can see, the number of circuits you need for your wiring harness will depend on the electrical accessories you have (or want to have) in your vehicle.

There's a lot to know about automotive wiring harnesses, and to be frank we've only scratched the surface here in our guide. As a service to our customers, we stand ready to answer the automotive wiring questions of everyone who buys a wiring harness from H&H Classic Parts.